Hanson Flap Gates

Hanson Flap Gates act as check valves that go out the end of a storm drain outlet so the water does not back up into the sewer drainage system. It creates a barrier between the high water in the drainage systems and the sewer system itself. Competitors have cast iron solutions but we use structural plate and reinforced channel with zinc rich epoxy paint on carbon steel; hot-dipped galvanized or stainless steel are also options. Our gates can be mounted on corrugated metal pipe, concrete pipe or head walls.

Specifications of Hanson Steel Automatic Flood Gates

The working principals of the Hanson Flood Gates are unique in design and have many advantages over other types at more economical prices. Patents are held on these unique features.

They are made of steel; are much lighter in weight; no danger of breakage and the transportation is much less.

They are quick and easy to install.

The angle position in which the flap is mounted permits the pipe to flow at full capacity.

If hit by floating objects they will close down momentarily and will not be torn off due to the angle of the lid to the flow . The steel lid will not break or crack as some cast iron types.

The Hanson Gate will open under much lower unseating heads due to the hinge and mounting design.

Debris is self cleaned from the gate lid due to easy opening feature.

Material Specifications

Steel Plate, Angle and Channel Iron ASTM A-36 "STRUCTURAL STEEL."

Stainless Steel Hinge Pins or Anchor Bolts. ASTMA-276, Type 303-304.

Stainless Steel Nuts and Bolts, etc., and Galvanized Nuts. FED. SPEC. FF-H-836c, NUT PLAINT: (HEX., SQUARE, CAP AND WELDING) NUT, SLOTTED

AND CASTELLATED, HEX., TYPE I, STYLE 1 FOR SQUARE NUTS. TYPE II, STYLE 4 FOR GALVANIZED AND CORROSION RESISTING STEEL.

BOLTS. FED. SPEC. FF-B-575b, "BOLTS, HEX. AND SQUARE," TYPE 2 for low carbon for galvanized and corrosion resisting steel bolts.

Bronze Bushings, ASTM designation B-145 or ASTM designation B-124-alloy 2.

Paint. FED. SPEC. TT-P-641, TYPE I OR II, ZINC DUST-ZINC OXIDE PRIMER OR S567 EPOXY ZINC RICH-GALVANIZED COATING. (Comparable to Galvanizing.)

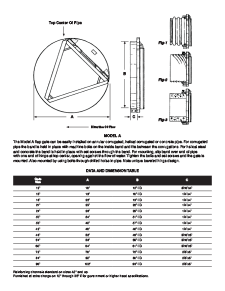

Gate Installation Instructions

The gates are easily installed. The band is held in place with machine bolts. For mounting, slip band over end of pipe with one end of hinge at top center, opening against the flow of water. Tighten the takeup bolts evenly, let flap lid hang plumb, adjust band to flap gate lid, then drill one 9/16" hole for one 1/2" bolt and place in hole (snug only - do not tighten). Make sure band is out to lid at all times before drilling another hole. Then drill one more hole and install bolt as above and continue until all are installed.

For concrete pipe mounting, they are held in place with set screws through the band into the concrete.